The application of industrial Internet of Things in manufacturing enterprises

-

Production equipment interconnection

Using the data interface provided by the digital production equipment, the production equipment is physically connected into a network, and the protocol transformation software is used to form a common IP network.

-

Item identification and location

RFID and other identification and positioning technologies are used to identify the raw materials, semi-finished products and finished products used in the production process, and the Internet of things technology is used to connect the system to the computer network, so as to complete the digital management of the quantity, location and information of responsible personnel.

-

Automatic energy consumption detection

Relevant devices are used to complete the automatic collection of electric energy, gas energy and heat energy consumption data, and these systems are connected to the Internet of Things, and the information function provided by the computer network is used to complete the management of these data.

-

Status inspection of production equipment

Wireless transmission technology is used to connect with the corresponding centralized control device to form a small Internet of things, and information technology is used to manage these data, and corresponding processing is made according to the requirements of enterprise production management.

-

Inform production site of important information remotely

Various information from the production site is transmitted to the corresponding equipment in real time through equipment interconnection, item identification and positioning, etc., and then transmitted to the handheld devices of enterprise managers at all levels in real time through public networks such as GSM for easy reading.

-

Production of accessories and products anti - theft.

RFID and other identification and positioning technologies are used to connect these items to the Internet of Things to realize the digital identification of items, regional positioning, personnel management authority, items and personnel management area and other management functions, so as to realize the orderly, documented and responsible circulation of items.

-

Assessment of the production

General production and processing enterprises in the production of front-line staff wages are piecework wages, this way time consuming, laborious, and due to manual assessment into human nature, it is difficult to achieve justice, fairness.

-

Environmental monitoring

Wireless sensor equipment installed in the sewage outlet of key enterprises can not only monitor the sewage discharge data of enterprises in real time, but also close the sewage outlet remotely to prevent the occurrence of sudden environmental pollution accidents.

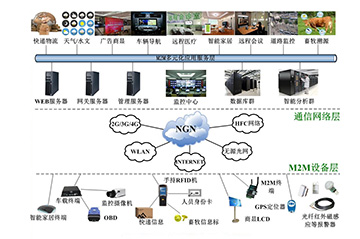

Industrial Internet of Things application Architecture and implementation

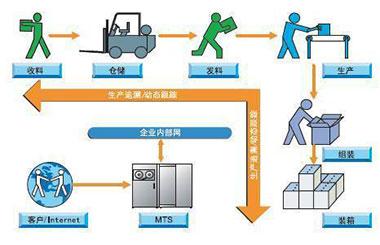

Production traceability management system

- ◆ planning and scheduling

- ◆ resource management

- ◆ process control

- ◆ production process control

- ◆ data acquisition

- ◆ quality management

- ◆ product traceability and recall

- ◆ statistical analysis

- ◆ system management

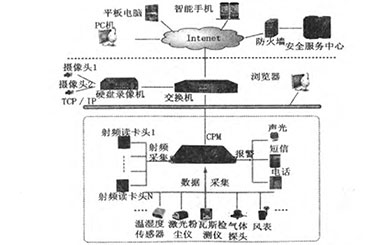

Security integrated monitoring and management system

- ◆ Information collection

- ◆ Information and communication

- ◆ Real-time monitoring

- ◆ Monitoring and early warning

- ◆ Information security

- ◆ Decision analysis

- ◆ Statistical analysis

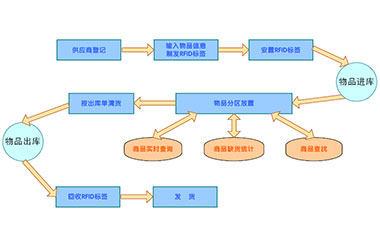

Warehouse and logistics management system

- ◆ The network architecture

- ◆ The working process

- ◆ System composition

- ◆ System advantage

- ◆ System implementation